“The selection of a contract manufacturing partner can be nerve racking but we have found the team at CMC efficient and effective. Some might say that our current packaging configuration is challenging, but the team at CMC consistently maintains a high quality standard while meeting or exceeding our timeline expectations. When I see our product in retail, I am reminded that we picked the correct contract manufacturing partner.”

Vice President – Mass Market Oral Care Marketer

Our Operations team is dedicated to providing innovative solutions to our customers’ packaging needs. The Continental Manufacturing Chemist team’s predictable performance strategy provides our customer’s with proven manufacturing capability while reducing costs and increasing productivity. These values are applied utilizing a life cycle approach to process improvement and development.

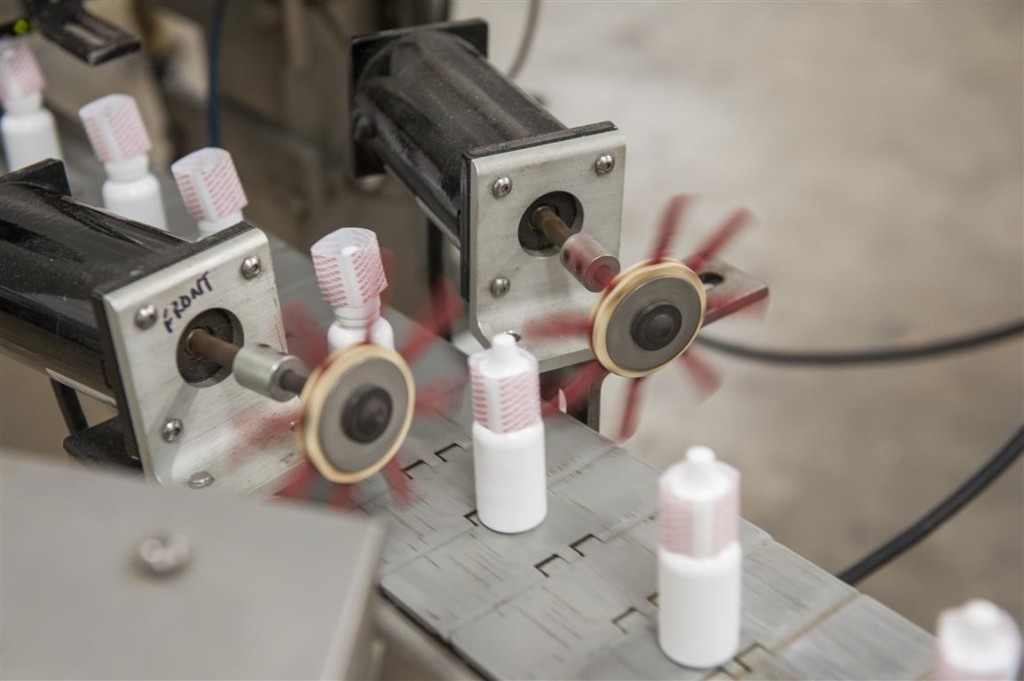

Continental Manufacturing Chemist offers a wide array of contract manufacturing capabilities. Our in-line filling equipment offers incredible flexibility with high throughput with a minimum of tooling required. Our tube equipment is industry leading Kalix equipment.

BATCHING

9 batch tanks ranging from 120 – 3,000 gallons capable of mixing liquids from water thin to heavy pastes. Agitation methods include lightening, shear and side sweep. De-aerator used to ensure fill weights on heavy creams and pastes.

FILLING & LABELING

Filling

- 8 production lines with fill sizes from 0.25oz – 1 gallon and up

- XP line for high alcohol products

- 2 Tube fillers

- Tub and jar filling

Labeling

- Multiple labelers capable of front / back or wrap labeling

- Multiple Spot labelers

- Custom built shrink labeler and steam tunnel

PACKOUT & ASSEMBLY

- Semi-automated cartoning equipment

- 3 lines dedicated to manual assembly and kitting

Where Solutions Flow

Continental Manufacturing Chemist, Inc. 912 South State Street – Madrid, Iowa 50156 United States PHONE (515) 795-2000 | FAX (515) 795-2954